- On sale!

- -50%

Paint Mixing Paddle

This medium duty mixing paddle is capable of mixing paint, coatings, sealers and light mortars.

£63.32 ex VAT.

Resincoat Anti-Slip Step Paint is a high strength coating to provide long lasting slip resistance to stairs and steps. This complete non-slip stair paint system withstands regular and high pedestrian traffic. Works well even when applied onto the stair riser with limited dripping. Manufactured in the UK, the epoxy formula is high strength and will last for many years.

This Anti-Slip Step and Stair Paint is available in a huge range of colours offering a highly decorative gloss finish. Ideal for both DIY and industrial users the paint can be applied to a wide range of substrates. Use it to rejuvenate your existing front door step whilst also giving it excellent anti-slip properties. Additionally the paint can be used in industrial and workplace settings offering a safe surface for users to walk on in all conditions.

The anti-slip profiles improves grip underfoot helping to reduce slips and trips. Customers have a choice of fine, medium or coarse with each providing a highly durable, tough design. Easy to apply the paint can be applied in a timely manner and once cured can withstand high traffic. Whether you want to coat interior or exterior surfaces this anti-slip paint is a great option that will provide a professional looking finish.

For areas where safety of staff and the public is paramount, this coating is the perfect solution. We offer three grades of sand blend to choose from to suit your needs. These are:

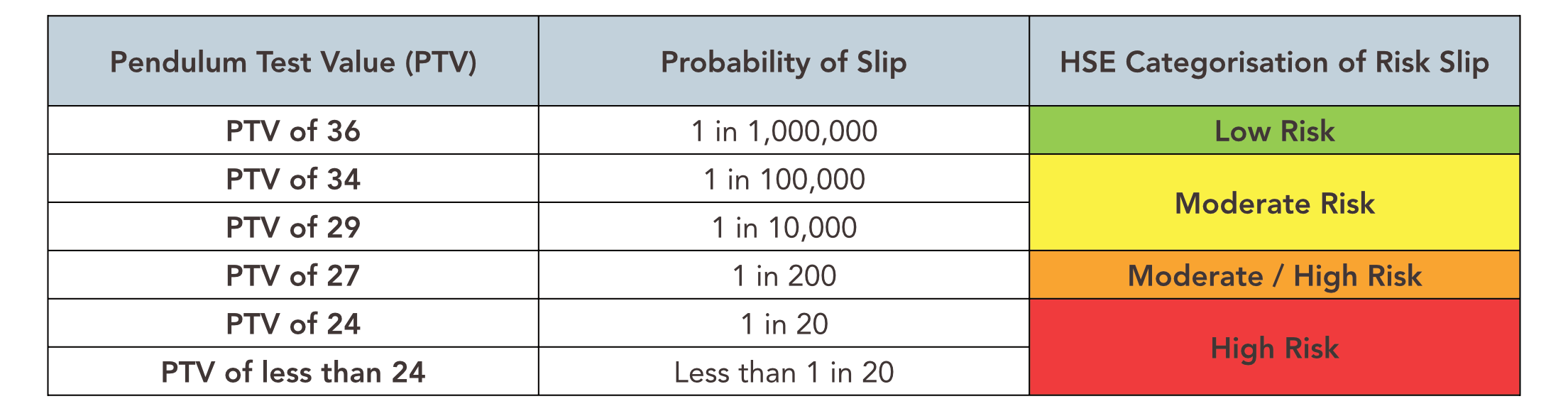

Our premier High Build Epoxy Anti-Slip Floor Paint is specifically formulated to meet and in many cases exceed guidelines set about by the Health and Safety Executive in the UK. Those guidelines state that floors should meet the following slip resistance ratings under both WET and DRY conditions when tested using Cooper pendulum testing equipment:

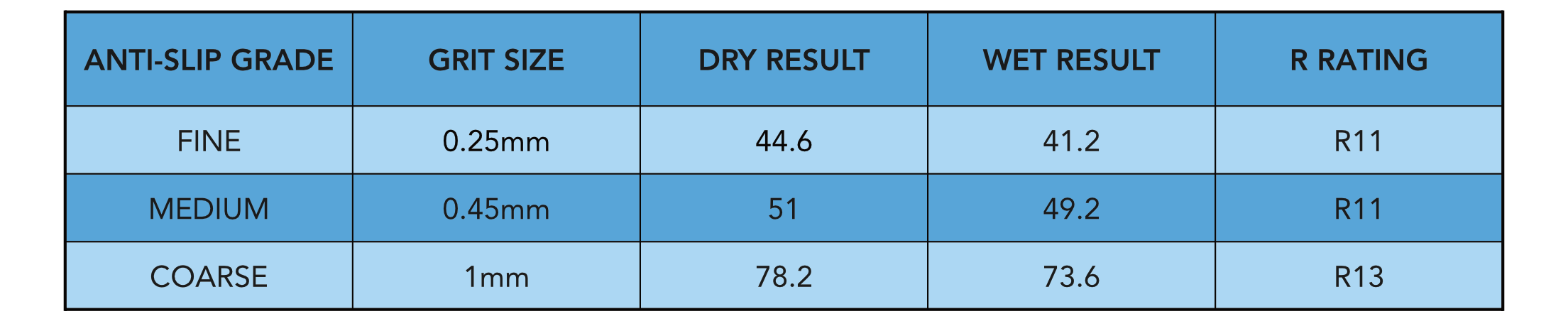

Below are Resincoat's HB Epoxy Anti-Slip Floor Paint test results under normal conditions:

The thickness and therefore effectiveness of our Anti Slip coatings are:

Fine: 0.25mm

Medium: 0.45mm

Coarse: 1mm

Please note: during application, and particularly with fine and medium, if the paint is applied too thickly, then the particles of anti-slip sand won't protrude through the surface, and wont work effectively.

Please see below for coverage rates. If you are coating a large area and would like expert advice, please call our team who will be happy to assist you.

1kg: 3-4m²

2.5kg: 8-10m²

Please note: the above coverage rates are per coat, in most cases we advise 2 coats.

Old paint finishes should be removed if flaking at all and the surface should be sanded to create a texture (also known as a mechanical key) prior to applying Resincoat Anti-Slip Step Paint System. When preparing for a floor coat, doing so mechanically (shot-blasting or grinding) is always advisable for best results, but if that is not possible then sanding the area or our Etch and Clean is a good alternative. After the surface has been completely abraded, thoroughly sweep and vacuum the area of any remaining dust or contaminants. For more information on preparation, please see technical data sheet.

Please note: Etch and Clean is only suitable for use on bare concrete.

• For new concrete floors or floors in good condition, prime with Resincoat Damp Tolerant Primer

• For dusty, old or weaker floors prime with Resincoat Deep Penetrating Primer

• For greasy floors with heavy oil residue clean thoroughly using a suitable degreaser scraping off any dust or dirt and then prime with Resincoat Oil Tolerant Primer

We advise when applying this product the ambient temperature is at least 7°C.

1. Mix Part A on its own with a mixing paddle attached to an electric drill for about 1 minute before adding ALL of Part B and continue to mix for another 90 seconds, keeping the paddle in suspension to avoid mixing air into the unit.

2. Pour entirety of the tin's contents into a plastic paint scuttle or tray.

3. Immediately begin applying your paint with a nylon-bonded resin suitable roller.

4. Use a brush around the edges to cut in (a second pair of hands can be useful for this stage).

5. Scatter in, by hand, the chosen aggregate into the wet coat and back roll. Allow this to cure. Brush off any aggregate that has not cured into the paint.

6. As soon as the first coat has started curing (is no longer tacky to touch) you can re-coat; this should take 12-24 hours.

7. Once fully cured the area is ok for foot traffic. Full chemical cure is 7 days.

PLEASE NOTE: The pot life of this product is 20 minutes. This means that once parts have been mixed, the paint will start to chemically cure after this time. Ensure you remove the paint from the tin in this window. The paint will then be workable on your floor for up to 40 minutes.

Pot life = Time to harden in pot following addition of hardener

Working Time = Time to apply product before it becomes unworkable

• Roller sleeves should be used once per coat, two coats will require two roller sleeves.

• This product is NOT UV stable therefore can discolour when exposed to regular sunlight. For areas with plenty of repeated sunlight, please coat with a coloured UVR coating such as Resincoat Chemical Resistant UVR Floor Coating for a UV stable finish.

• This product should NOT be split. Taking smaller quantities from each tin, even if measured correctly, may cause issues with activating.

• This product is NOT self levelling.

• If you require a clear epoxy coating visit our clear epoxy product here.

Data sheet

Specific References