Unmatched 2-Part Durability with Superior Anti-Slip Traction

Resincoat Non-Slip Decking Paint is the the ultimate solution for creating a safe, attractive, and long-lasting decking surface. This premium two-part UVR anti-slip coating is engineered for exceptional durability, making it far superior to single pack coatings. Perfect for domestic, industrial, and commercial applications, it offers outstanding performance even in areas with heavy foot traffic. The gloss finish enhances the aesthetic appeal of any decking, while the UV and weather-resistant properties ensure it withstands the harshest conditions. Ready for use in just 24 hours, this easy-to-clean, high-coverage coating provides superior traction to prevent slips and falls, ensuring the safety of everyone who steps on your deck.

Our decking paint is proudly manufactured in the UK to the highest standard. Resistant to weathering, the formula is highly durable making it ideal for areas of heavy foot traffic. The anti-slip additive ensures your surface is safe for users to walk on even when damp or wet. Besides timber decking, the coating adheres well to concrete, metal and GRP, subject to priming requirements. For alternative substrate enquiries, please contact us for guidance.

The thickness and therefore effectiveness of our Anti Slip coatings are:

Fine: 0.25mm

Medium: 0.45mm

Please note: during application if the paint is applied too thickly, then the particles of anti-slip sand won't protrude through the surface and it won't work effectively.

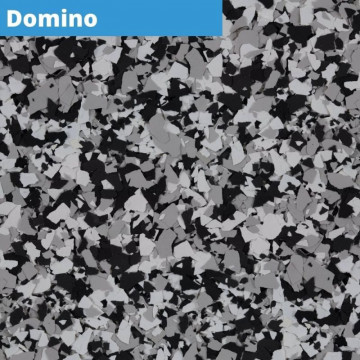

Colour Guide

Coverage Rates

Please see below for coverage rates. If you are coating a large area and would like expert advice, please call our team who will be happy to assist you.

1kg: up to 5m²

2.5kg: up to 12.5m²

Please note: the above coverage rates are per coat, in most cases we advise 2 coats, and is very dependant on the porosity of the wood.

Application Guide

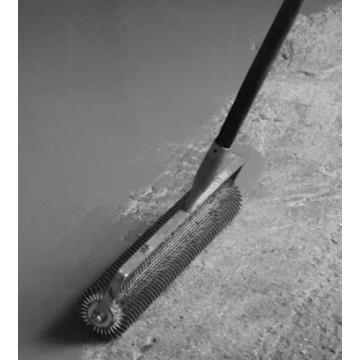

Preparation

Old paint finishes should be removed if flaking at all and the surface should be sanded to create a texture (also known as a mechanical key) prior to applying Resincoat Non Slip Decking Paint. When preparing for a floor coat, doing so mechanically (shot-blasting or grinding) is always advisable for best results, but if that is not possible then sanding the area or our Etch and Clean is a good alternative. After the surface has been completely abraded, thoroughly sweep and vacuum the area of any remaining dust or contaminants. For more information on preparation, please see technical data sheet.

Please note: Etch and Clean is only suitable for use on bare concrete.

Priming

• For best results prime with Resincoat Metal and Wood Primer. Primer is recommended for use on solid, rigid wood floors only.

Application

We advise when applying this product the ambient temperature is at least 7°C.

1. Mix Part A on its own with a mixing paddle attached to an electric drill for about 1 minute before adding ALL of Part B and continue to mix for another 90 seconds, keeping the paddle in suspension to avoid mixing air into the unit.

2. Pour entirety of the tin's contents into a plastic paint scuttle or tray.

3. Immediately begin applying your paint with a nylon-bonded resin suitable roller.

4. Use a brush around the edges to cut in (a second pair of hands can be useful for this stage).

5. As soon as the first coat has started curing (is no longer tacky to touch) you can re-coat; this should take 12-16 hours at 10°C.

6. If course anti-slip profile was purchased, the aggregate will have come separately. This must be added manually, typically by scattering by hand it onto a still-wet first coat of paint and then back-rolling the paint.

7. The cured final coat is ok for foot traffic. Heavy objects, however, should be left off the new coating for the first 48 hours and chemicals, including water, should not be introduced for the first 4 days (Full chemical cure).

PLEASE NOTE: The pot life of this product is 30 minutes. This means that once parts have been mixed, the paint will start to chemically cure after this time. Ensure you remove the paint from the tin in this window. The paint will then be workable on your floor for up to 60 minutes.

Pot life = Time to harden in pot following addition of hardener

Working Time = Time to apply product before it becomes unworkable

Useful Information

• Roller sleeves should be used once per coat, two coats will require two roller sleeves.

• This product should NOT be split. Taking smaller quantities from each tin, even if measured correctly, may cause issues with activating.

• This product is NOT self levelling.