Flexibility Meets Strength: The Resincoat Fibre Reinforced Advantage

Elevate your flooring projects with Resincoat Self Levelling Compound the fibre-reinforced formula designed for superior performance and precision. This premium compound stands apart with its exceptional quality, guaranteeing unmatched floor smoothing precision for a variety of indoor surfaces. Whether you're preparing for a sophisticated resin floor or looking to enhance underfloor heating efficiency, its versatile application from 3-50mm in a single pour makes it the ideal choice. Its rapid setting time ensures that spaces are foot traffic-ready in just 4 hours, minimising downtime and accelerating project timelines. With Resincoat, you're not just choosing a product; you're investing in a solution that combines ease of use with durability and premium quality.

Conforms to BS EN 13813 and CT C35 F9

Coverage Rates

This product can be applied at depths between 3-50mm. For every 1mm thickness 1.7kg of dry powder per square metre will be required, for example:

- 1m2 at 5mm thickness will require 8.5kg of dry powder.

- 1m2 at 10mm thickness will require 17kg of dry powder.

Application Guide

Preparation

Before applying the self levelling screed there are some critical steps you must follow to prepare your surface to ensure good adhesion. Surfaces should be mechanically prepared and in a sound, dry condition. Any existing concrete or cement screeds must be fully cured and any laitance or loose materials removed, ensuring that the area is cleaned and vacuumed thoroughly before undertaking the following:

1. The floor must be primed using an applicable epoxy primer (see "Priming" section below). The primer you use will depend on your current floor condition, if using a damp tolerant or oil tolerant primer, then 1 coat should be applied and left to cure before a second coat is applied. All other primers will require just 1 coat.

2. Whilst the primer is still wet fully, cover the area with an aggregate like our anti-slip additive in a medium profile.

3. This is then left to cure to create a sandpaper like surface.

4. Once fully cured (typically 12-24 hours, depending on the primer used) brush off any excess aggregate and address any glossy patches by applying some more primer and aggregate.

5. Once fully covered in aggregate and cured, you can now begin applying the self levelling compound.

Priming

• For new concrete floors or floors in good condition, prime with Resincoat Damp Tolerant Primer

• For dusty, old or weaker floors prime with Resincoat Deep Penetrating Primer

• For greasy floors with heavy oil residue clean thoroughly using a suitable degreaser scraping off any dust or dirt and then prime with Resincoat Oil Tolerant Primer

Application

Before you begin ensure the subfloor and surrounding air temperatures will not drop below 5 degrees during application and throughout the subsequent 7 day full cure. Light ventilation is recommended, particularly in enclosed areas. Resincoat Self Levelling Compound can be applied by hand mixing, be sure to mix with cold water to avoid reducing the product's working time

See below for the relevant quantities of water required based on the size screed you have:

| 20kg |

- |

4.0 - 4.4L of water |

| 10kg |

- |

2.0 -2.2L of water |

| 5kg |

- |

1.0 - 1.1L of water |

1. Pour the correct amount of clean, cold water into an oversized bucket and gradually add the power, whilst mixing continuously with a mixing paddle attached to an electric drill.

2. Once you have added all of your powder, continue to mix for a further two minutes until a lump-free smooth material is attained.

3. Pour the product directly on to your substrate using a smooth, steel trowel to spread to the desired application depth.

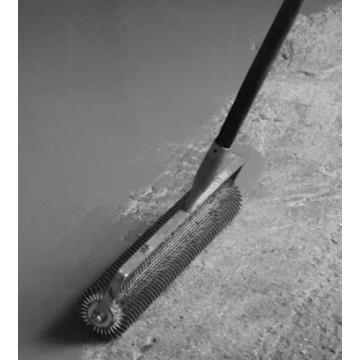

4. A spike roller may also be used whilst the product is still fluid to minimise air entrapment and give a fully uniformed finish.

5. Leave to fully harden (Full compressive strength is reached after roughly 28 days, more specifically it dries at one mm/1 day)

PLEASE NOTE: The pot life of this product is 20 minutes. This means that once parts have been mixed, the product will start to harden and become unworkable after this time.

Finishing and Decoration

After being left to dry (1mm/day), a relative humidity of 75% should be achieved before you are able to apply your chosen primer and two coats of Resincoat paint.

Useful Information

• For industrial use: consider a pump-screed method which will allow coverage of larger areas quickly producing a smooth, effective result.

• IMPORTANT: product must be stored under cover, protected from the weather and in dry conditions so that the packaging is not exposed to moisture.