DESCRIPTION

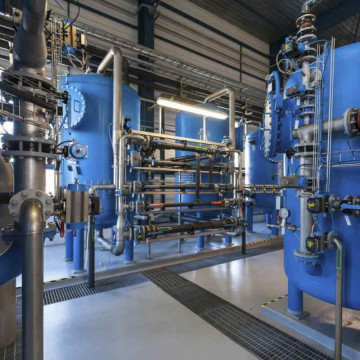

The epoxy flake system is a strong industrial coating providing high levels of durability ideal for both domestic & industrial use. The flooring would look great in any garage floor, showroom, gym and any other industrial space. Our system makes concrete floors look highly attractive whilst also providing a high quality finish. The base and top coat consist of our best-selling epoxy floor coating proudly manufactured in the UK.

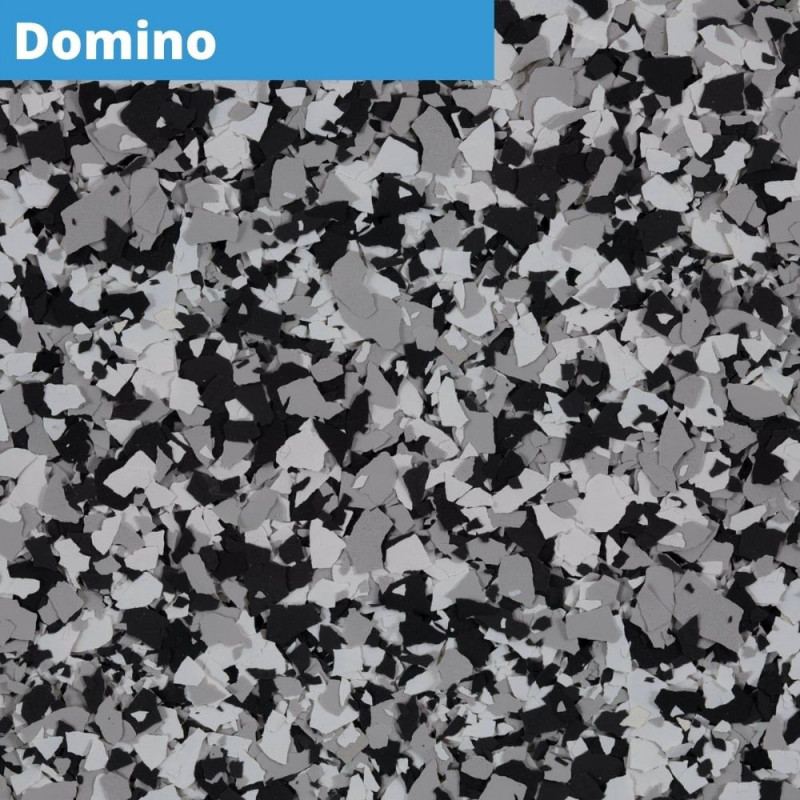

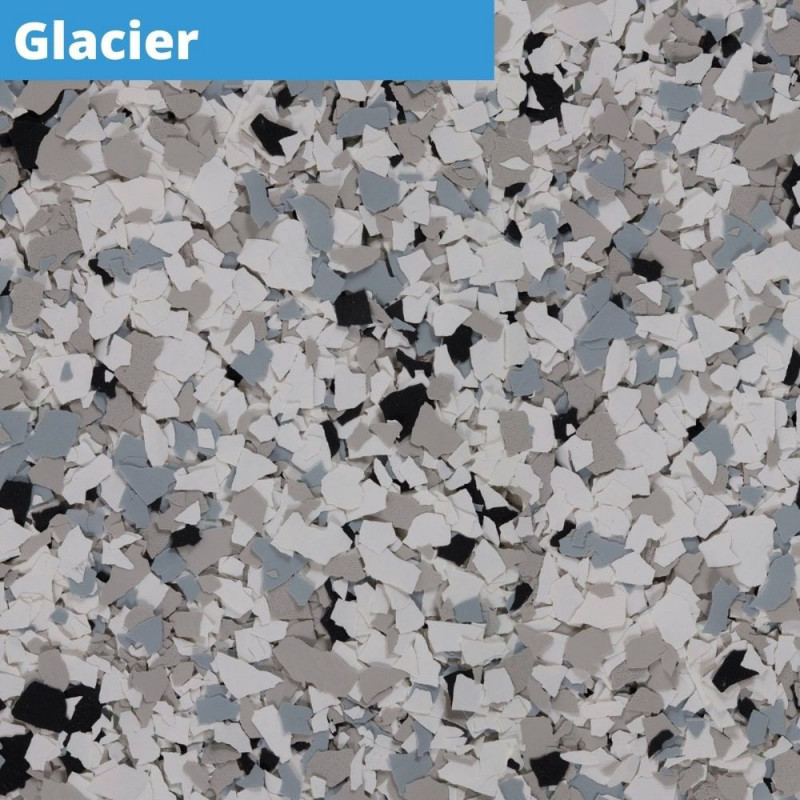

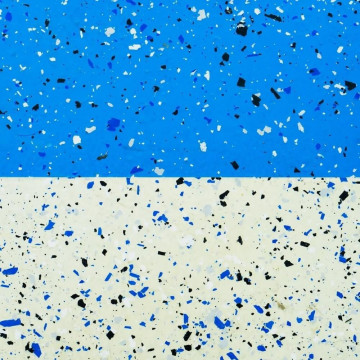

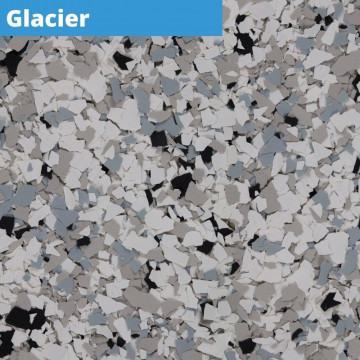

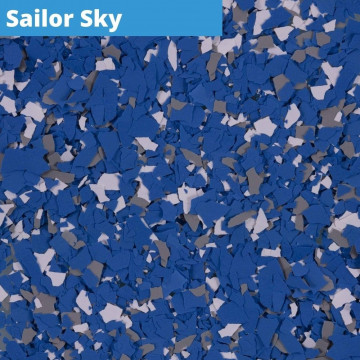

Flake Finishes:

There are two main flakes finishes; full blind & scatter.

- Full Blind - complete covering of flakes across the entire surface.

- Scatter – a scattering of flakes across your surface.

KIT QUANTITIES

See below the exact quantities for each product that is supplied in our single garage floor paint kits:

| 10m2 Kit Contains |

20m2 Kit Contains |

30m2 Kit Contains |

| 2 x 2.5kg Epoxy Garage Floor Paint |

2 x 5kg Epoxy Garage Floor Paint |

2 x 5kg Epoxy Garage Floor Paint |

| Scatter: 0.5kg / Full Blind: 5kg |

Scatter: 1kg / Full Blind: 10kg |

2 x 2.5kg Epoxy Garage Floor Paint |

| 1 x 1kg Fast Cure Top Coat |

2 x 1kg Fast Cure Top Coat |

Scatter: 1.5kg / Full Blind: 15kg |

| 1 x Application Kit |

1 x Application Kit |

3 x 1kg Fast Cure Top Coat |

| 1 x Spiked Shoes (One size fits all) |

1 x Spiked Shoes (One size fits all) |

1 x Application Kit |

|

|

1 x Spiked Shoes (One size fits all) |

APPLICATION GUIDE

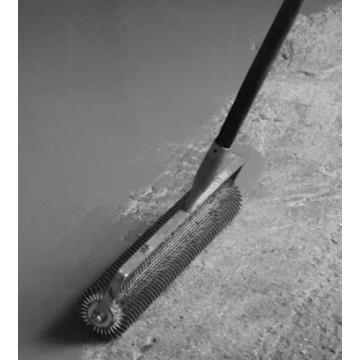

Preparation

Old paint finishes should be removed if flaking at all and the surface should be sanded to create a texture (also known as a mechanical key) prior to applying Resincoat Epoxy Flake Flooring System. When preparing for a floor coat, doing so mechanically (shot-blasting or grinding) is always advisable for best results, but if that is not possible then sanding the area or our Etch and Clean is a good alternative. After the surface has been completely abraded, thoroughly sweep and vacuum the area of any remaining dust or contaminants. For more information on preparation, please see technical data sheet.

Please note: Etch and Clean is only suitable for use on bare concrete.

Priming

• For new concrete floors or floors in good condition, prime with Resincoat Damp Tolerant Primer

• For dusty, old or weaker floors prime with Resincoat Deep Penetrating Primer

• For greasy floors with heavy oil residue clean thoroughly using a suitable degreaser, scraping off any dust or dirt and then priming with Resincoat Oil Tolerant Primer

Application

We advise when applying this product the ambient temperature is at least 7°C.

1. Beginning with your primer – mix part A in the tin for a minute before adding 100% of part B and mixing for a further 60 seconds

2. Apply the primer across the area and leave to cure for 12-24 hours

3. Once the coating has cured, mix first coat of our epoxy floor paint together with a drill & paddle for at least 1 minute

4. Pour the contents into a paint scuttle

5. Immediately begin painting your floor using an epoxy roller - use a brush around the edges for a smooth finish (a second pair of hands comes in useful)

6. Once you have applied coat 1 leave to cure until touch dry approximately 12-24 hours

7. Repeat steps 3 - 6 when applying your second coat

8. Apply the flakes when the paint is still wet (depending upon required finish either sprinkle ad hoc or full blind

9. Leave the coating to cure until touch dry before brushing off any excess flakes

10. Seal the flakes in place with the clear top coat – mix part A in the tin for a minute before adding 100% of part B and mixing for a further 60 seconds

11. Pour content into a paint scuttle

12. Begin painting your flake floor using an roller

13. Leave for 3 hours to fully cure - note the top coat will cure much faster than the rest of the system

PLEASE NOTE: The pot life of this product is 20 minutes. This means that once parts have been mixed, the paint will start to chemically cure after this time. Ensure you remove the paint from the tin in this window. The paint will then be workable on your floor for up to 40 minutes.

Pot life = Time to harden in pot following addition of hardener

Working Time = Time to apply product before it becomes unworkable

USEFUL INFORMATION

• Roller sleeves should be used once per coat, two coats will require two roller sleeves.

• This product should NOT be split. Taking smaller quantities from each tin, even if measured correctly, may cause issues with activating.

• This product is NOT self levelling.