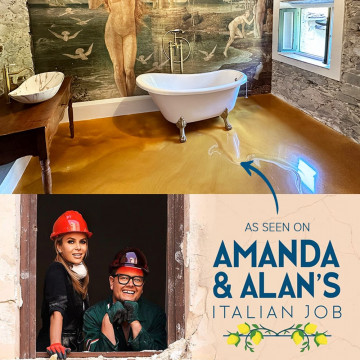

Each component of our Metallic Epoxy Flooring System has been specially formulated, allowing you to create stunning decorative surfaces. The beauty of this system is it gives the user full control over each creative aspect of the project, crafting exquisite, bespoke marble-like flooring in either your home or commercial setting. The smooth high gloss finish exudes style and is also extremely easy to clean and maintain. Starting with the Resincoat Metallic Epoxy Base Coat, white tones suiting lighter metallic styling, whilst the grey to black suits a darker, richer project.

Easy to install the Metallic Epoxy Flooring System, can be applied using standard DIY techniques along with our expert guidance saving you time and money. Any surface that is stable and has a porous surface can be transformed including wood, concrete, plastic and more (surface has to be perfectly smooth, no tiles or grouts, joints can be visible).

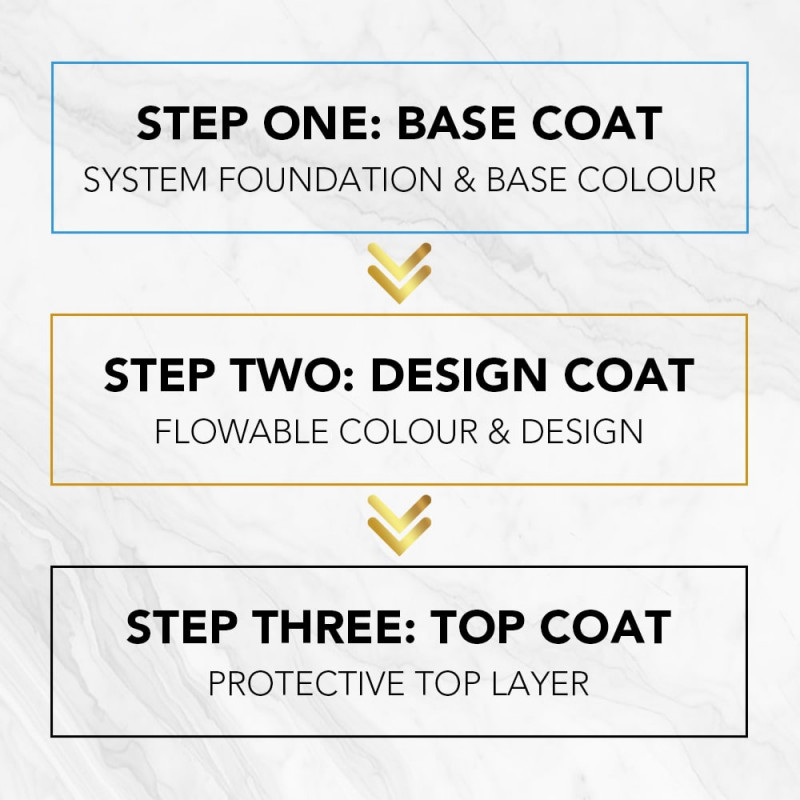

WHAT YOU NEED FOR A METALLIC EPOXY FLOORING SYSTEM:

Resincoat Metallic Epoxy Base Coat (Step 1): The Resincoat Metallic Epoxy Base coat sets the tone of your floor. The base coat is available in white, grey or black and seals & primes your floor.

Resincoat Metallic Epoxy Design Coat (Step 2): Resincoat Metallic Epoxy Design Coat is the heart of the Metallic Epoxy Flooring System. It is a two-part clear epoxy resin pigmented with your choice of colours to create your own metallic or marble effect flooring design.

Resincoat Metallic Top Coat (Step 3): Resincoat Metallic Top Coat is available in two options depending on your needs. The first is a single-pack water based top coat that is exceptionally easy to install, whilst the second option is a two-part high gloss UVR top coat which offers a more durable & robust finish, ideal for areas with high foot traffic.

HOW TO APPLY:

Before applying the Resincoat Metallic Epoxy Base Coat ensure your floor is perfectly smooth, screeding if necessary. Old paint finishes should be removed if flaking at all and the surface should be sanded to create a texture (also known as a mechanical key) prior to applying the Resincoat Metallic Epoxy Base Coat. When preparing the floor for a coating, doing so mechanically (shot-blasting or grinding) is always advisable for best results, but if that is not possible then sanding the area or our Etch and Clean is a good alternative. After the surface has been completely abraded, thoroughly sweep and vacuum the area of any remaining dust or contaminants. For more information on preparation, please see the technical data sheet.

Please note: Etch and Clean is only suitable for use on bare concrete.

1. Mix Part A on its own with a mixing paddle attached to an electric drill for about 1 minute before adding ALL of Part B and continue to mix for another 90 seconds, keeping the paddle in suspension to avoid mixing air into the unit.

2. Pour the entirety of the tin's contents into a plastic paint scuttle or tray or pour the contents directly on to your floor.

3. Immediately begin applying your paint with a nylon-bonded resin suitable roller.

4. Use a brush around the edges to cut in (a second pair of hands can be useful for this stage).

5. As soon as the Resincoat Metallic Epoxy Base Coat has started curing (is no longer tacky to touch) you can coat with the first Resincoat Metallic Epoxy Design Coat; this should take 12-24 hours.

Please note: you may wish to further sand down in between coats for the ultra-smooth finish. Please refer to the datasheet for additional advice on application.

Good to know:

• Roller sleeves should be used once per coat, two coats will require two roller sleeves.

• This product should NOT be split. Taking smaller quantities from each tin, even if measured correctly, may cause issues with activating.

• This product is applied by roller as a paint and is NOT self levelling.

• Be advised: in some cases, white or light colour systems may experience minor discolouration.