DESCRIPTION

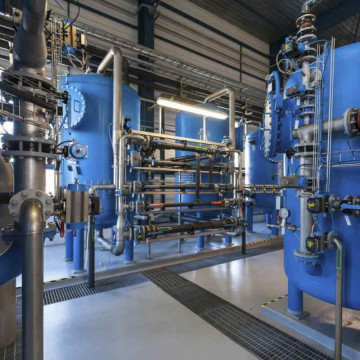

Excellent Chemical Resistance

Resincoat chemical resistant floor coating has been lab tested to withstand chemical spills and other unwanted liquid damage. Composed of a pigmented aliphatic PU resin this paint is sure to be extremely durable whilst being easy to clean and maintain. Our chemical resistant floor paint is commonly applied as a top coat over other heavy duty industrial floor paints such as our Factory Floor Paint for additional chemical resistance.

Brewery Floor Paint

Resincoat Chemical Resistant UVR Floor Paint is used by a growing number of breweries in the UK thanks to it's resistant properties preventing erosion/flaking of the coating when exposed to alcohol based liquid spills. The formula is also exceptionally easy to clean saving time in the day to day upkeep of a brewing environment. Despite the coatings high industrial strength it is easy enough to apply for a non-expert user, making it a great option for those with little or no installation knowledge. For further advice on this type of application, why not contact our team on 0330 0570 695 who will be happy to discuss your upcoming project and answer any questions you might have.

COVERAGE RATES

Please see below for coverage rates. If you are coating a large area and would like expert advice, please call our team who will be happy to assist you.

2.5kg: 15-20m²

Please note: the above coverage rates are per coat, in most cases we advise 2 coats.

APPLICATION GUIDE

Preparation

Old paint finishes should be removed if flaking at all and the surface should be sanded to create a texture (also known as a mechanical key) prior to applying Resincoat Chemical Resistant UVR Floor Paint. When preparing for a floor coat, doing so mechanically (shot-blasting or grinding) is always advisable for best results, but if that is not possible then sanding the area or our Etch and Clean is a good alternative. After the surface has been completely abraded, thoroughly sweep and vacuum the area of any remaining dust or contaminants. For more information on preparation, please see technical data sheet.

Please note: Etch and Clean is only suitable for use on bare concrete.

Priming

• For new concrete floors or floors in good condition, prime with Resincoat Damp Tolerant Primer

• For dusty, old or weaker floors prime with Resincoat Deep Penetrating Primer

• For greasy floors with heavy oil residue clean thoroughly using a suitable degreaser scraping off any dust or dirt and then prime with Resincoat Oil Tolerant Primer

Application

We advise when applying this product the ambient temperature is at least 7°C.

1. Mix Part A on its own with a mixing paddle attached to an electric drill for about 1 minute before adding ALL of Part B and continue to mix for another 90 seconds, keeping the paddle in suspension to avoid mixing air into the unit.

2. Pour entirety of the tin's contents into a plastic paint scuttle or tray.

3. Immediately begin applying your paint with a nylon-bonded resin suitable roller.

4. Use a brush around the edges to cut in (a second pair of hands can be useful for this stage).

5. As soon as the first coat has started curing (is no longer tacky to touch) you can re-coat; this should take 12-16 hours at 10°C.

6. The cured final coat is ok for foot traffic. Cars and heavy objects, however, should be left off the new coating for the first 48 hours and chemicals including water should not be introduced for the first 4 days (Full chemical cure).

PLEASE NOTE: The pot life of this product is 30 minutes. This means that once parts have been mixed, the paint will start to chemically cure after this time. Ensure you remove the paint from the tin in this window. The paint will then be workable on your floor for up to 40-60 minutes.

Pot life = Time to harden in pot following addition of hardener

Working Time = Time to apply product before it becomes unworkable

USEFUL INFORMATION

• Roller sleeves should be used once per coat, two coats will require two roller sleeves.

• Please note: there may be colour differences between this product and our Epoxy Floor Paint products.

• This product should NOT be split. Taking smaller quantities from each tin, even if measured correctly, may cause issues with activating.

• This product is NOT self levelling.